Blockwork

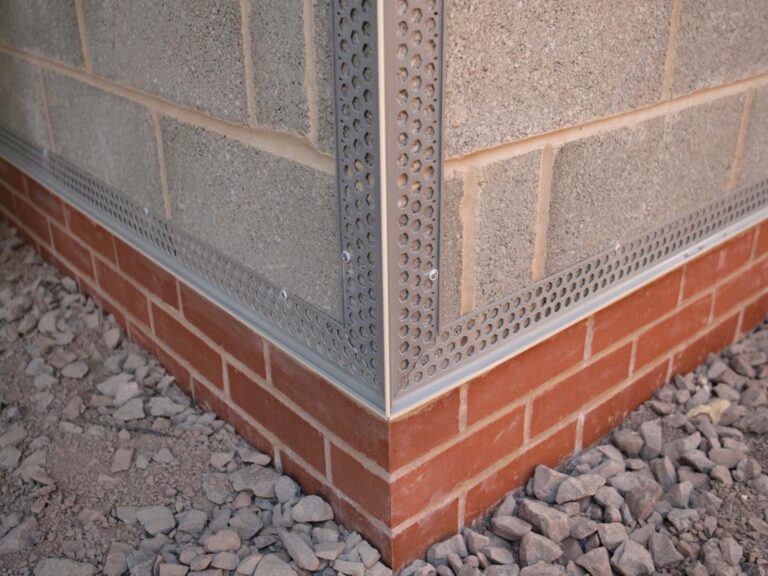

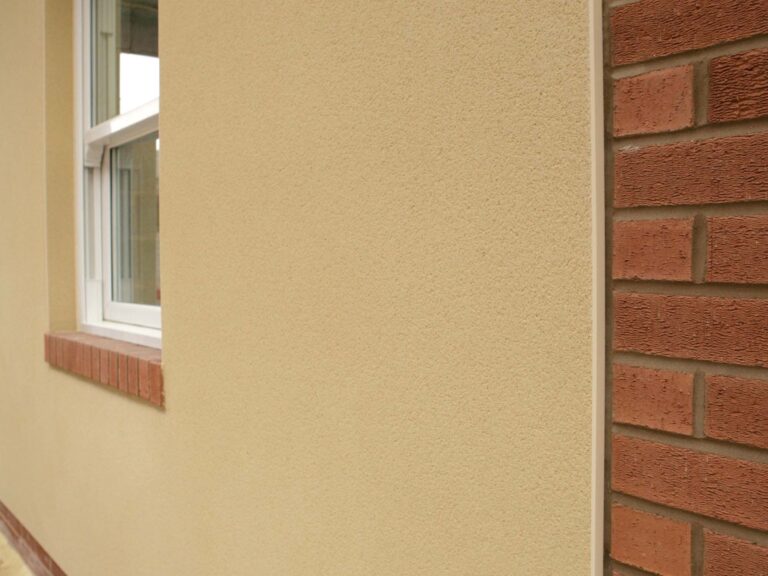

On blockwork, beads are set onto render dabs to the required depth and plumbed straight. Adhesive mortar can also be used for faster drying and to prevent slipping. Larger profiles, particularly wide wing beads, can be fixed with non-corrosive mechanical fixings alone as the flexible wings take up irregularities in the background, with the strong arris remaining straight. Nail clouts or hammer-in plug fixings are suitable for this.

Timber frame and external wall insulation systems

On timber frame and external wall insulation systems, there is no need to set the beads onto render or adhesive mortar if the surface is level. Suitable fixings should be chosen depending on the background.